In a rapidly evolving business landscape, costly errors associated with manual data extraction and analysis are giving way to automation powerhouse applications. As industries continue to embrace digital transformation, the utilization of automation technologies has surged, offering businesses the means to optimize their operational workflows, improve resource utilization, and achieve unparalleled efficiency. Computer-aided design (CAD) automation has emerged as a game-changer, with the potential to revolutionize a wide array of industries.

These insights into CAD Data Extraction are based on experience working with businesses to streamline their workflows.

What is Automated CAD data Extraction and how does it work?

Automated CAD data extraction is a technology-driven process that enables the automatic retrieval of specific information and data from Computer-Aided Design (CAD) files without manual intervention. The technology uses advanced algorithms, OCR technology, and machine learning to efficiently retrieve and structure data from CAD files, contributing to enhanced productivity, reduced errors, and improved data utilization.

These are the various phases involved in automating the data extraction process from visual CAD diagrams:

1. File Parsing: The process begins by parsing the CAD file, which could be in formats like DWG (AutoCAD), DXF, STEP, or others. During this step, the system reads the file’s structure and identifies different entities, layers, and objects within the CAD design.

2. Object Detection algorithms: Automated CAD data extraction systems employ object detection algorithms to identify and categorize elements within the CAD design. This includes recognizing lines, curves, text, dimensions, symbol s, and other geometric and textual components.

3. Attribute Extraction: Once objects are identified, the system extracts specific attributes associated with each element. For instance, it might extract dimensions, materials, annotations, and geometric properties like coordinates, angles, and distances.

4. Data Validation: Extracted data is then validated to ensure accuracy and consistency. This step involves checking extracted values against predefined rules and standards to confirm that they make sense within the context of the CAD design.

5. Data Structuring: Extracted data is organized and structured into a format that is usable for further analysis or integration with other software systems. This may involve converting the data into a standardized format or database entries.

6. Text Recognition: For textual data, such as labels, annotations, or notes within the CAD design, Optical Character Recognition (OCR) technology may be used to convert images of text into machine-readable text. This makes it possible to extract and analyze textual information.

7. Automation Rules: Automated CAD data extraction systems can be configured with specific rules and templates tailored to the needs of the industry or organization. These rules govern how data is extracted, validated, and structured, ensuring consistency and accuracy.

8. Machine Learning and AI: Some advanced CAD data extraction systems leverage machine learning and artificial intelligence (AI) algorithms to continuously improve their accuracy and adapt to varying CAD designs and formats. Over time, they learn to recognize patterns and optimize extraction processes.

9. User Interface: Many CAD data extraction tools offer user-friendly interfaces that allow users to define extraction parameters, specify what data to retrieve, and review extracted information. These interfaces may use drag-and-drop functionality or scripting for customization.

10. Integration: Extracted data can be integrated with various software applications, such as Product Lifecycle Management (PLM) systems, Enterprise Resource Planning (ERP) systems, or data analytics tools. This integration allows for seamless data sharing and utilization across the organization.

Unleashing the power of Automated CAD Data Extraction across Industries

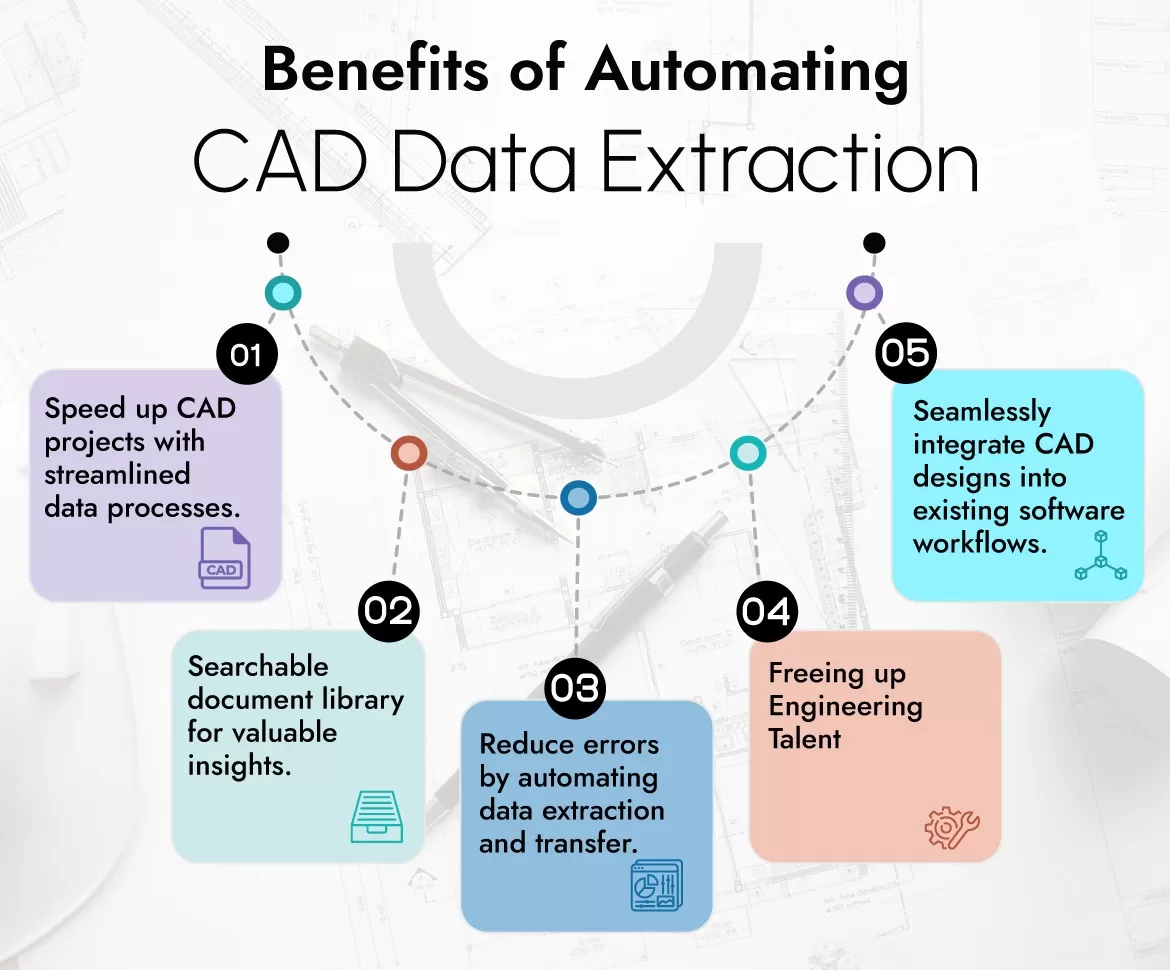

CAD automation is reshaping industries by automating manual processes and offering invaluable insights for decision-makers. One of its primary functionalities is data extraction from intricate CAD designs, which provides crucial information for analytical and developmental purposes.

These industries leverage AutoCAD data extraction to streamline their workflows, reduce errors, enhance precision, and ultimately achieve greater efficiency and competitiveness.

Streamlined Manufacturing and Engineering Processes

CAD extraction tools automatically extract design data such as dimensions, materials, and tolerances, significantly reducing errors and ensuring precise production. This translates into tangible cost savings and enhanced product quality.

Quality-related expenses are believed to account for a significant portion, potentially up to 20%, of total sales revenue. This inefficiency poses challenges for both original equipment manufacturers (OEMs) and small manufacturing businesses.

Automating the creation of Bills of Materials (BOM) from CAD files can eliminate manual data entry errors. Research from Aberdeen Group reveals that businesses leveraging CAD-driven BOM automation experience a 50% reduction in engineering change order cycle times.

Also Read: The Benefits of Automated Invoice Processing

Accelerated Architecture and Construction Projects with Automation

CAD extraction expedites cost estimation and bidding processes by automating the quantification of materials needed for construction projects. This efficiency can result in shorter project timelines and higher profit margins.

Collaboration and change management in construction are vital. CAD automation facilitates design version comparisons, reducing the likelihood of costly errors.

In the construction sector, such errors can account for up to 5% of total project costs, according to the Construction Industry Institute (CII).

CAD Data Automation for Precision in Automotive and Aerospace Industries

Component Analysis – CAD extraction or specifically data extraction autocad files assists in analyzing and optimizing designs for weight, strength, and efficiency. These optimizations are crucial in the automotive and aerospace sectors, where efficiency directly impacts fuel economy and safety.

The automotive industry, in particular, benefits from CAD automation’s ability to streamline the transfer of design data to simulation software. According to a study by Frost & Sullivan, automakers utilizing CAD automation have reduced time-to-market by 15% on average.

PCB Design Data for Electronics Industry

PCB Design: CAD extraction simplifies issue identification and resolution in electronic products by extracting data from PCB designs. This translates to faster product development cycles and more competitive market entry.

Automation of component data extraction from AutoCAD files streamlines sourcing and supply chain management. The cost of component shortages or delays can be substantial, with supply chain disruptions costing companies an average of 34% in operating income, according to a study by Accenture.

Customization in Consumer Goods and Retail

CAD extraction allows for tailored products through efficient product customization, adapting design parameters to meet customer preferences. This personalization is especially relevant in consumer goods, where customer satisfaction directly impacts brand loyalty and revenue.

Speeding up the prototyping process through CAD data extraction accelerates time-to-market. According to a survey by Wohlers Associates, companies utilizing CAD-driven 3D printing reported an average time savings of 57% in the prototype development phase.

3D models generated from CAD data enhance virtual visual merchandising and marketing efforts, resulting in higher customer engagement and conversion rates.

Innovation in Healthcare and Medical Devices using CAD Data

Precision and regulatory compliance are paramount in medical device design. CAD extraction ensures adherence to standards and accelerates the approval process, ultimately leading to faster product launches.

The ability to efficiently design and manufacture custom implants and prosthetics through CAD extraction capabilities is revolutionizing the healthcare industry. Patients benefit from more precise and personalized medical solutions.

Efficiency in Oil and Gas, Energy, and Utilities

According to the World Economic Forum, companies in the oil and gas sector that invest in digital technologies, including CAD automation, can achieve operational cost reductions of up to 20%.

CAD extraction aids in designing and maintaining intricate industrial plants, pipelines, and energy infrastructure. This leads to reduced downtime and enhanced operational efficiency.

Efficiently generate maintenance plans and documentation for equipment and facilities with CAD data extraction. Preventive maintenance can reduce downtime by up to 18%, according to a report by Plant Engineering.

Visual Merchandising: Reverse Indexing: Uncovering the Origins of Design Elements

In addition to CAD-related services, the emerging trend of reverse indexing is gaining traction. This process involves tracing specific information back to its origin, especially within CAD, to identify the origins of design elements or understand interdependencies within a design. Here’s how reverse indexing is making an impact:

Reverse indexing can be invaluable in quality control, design optimization, and product innovation. By understanding the origins of design elements, businesses can make informed decisions that lead to more efficient and effective product development processes.

Final words…

Before embarking on your CAD automation journey, it’s crucial to establish a well-defined purpose. What specific issues or obstacles are you aiming to address? What are the anticipated advantages or results of automation, and how will you quantify them? By crafting SMART (Specific, Measurable, Achievable, Relevant, Time-bound) objectives, you’ll pave the way for the effective planning, execution, and tracking of your CAD automation initiatives.

Set up a discussion with our team of Automation experts to get business-driven insights.

Pravin Kumar

He is a seasoned machine learning engineer with a wealth of hands-on experience .Pravin Kumar has a strong foundation in OCR, computer vision, and deep learning and leads the ML team at iTech India. He is an expert in a diverse range of programming languages and frameworks, including Python, CPP, Scala, JS, and React, and has a deep understanding of machine learning algorithms and techniques. He and his team have broken new ground in a wide array of projects spanning image recognition, object detection, and text extraction. This has enabled him to tackle complex projects and deliver top-tier results for real-world challenges.