We have all been here. Online purchasing has advanced in the last 5 years and Amazon to a large part has made us as customers expect more. Whether as individuals or large organizational requirements, logistics is an important piece in almost all value chains. The need to optimize supply chains is seeing the advance of many supply chain disruption trends.

Consider this, The International Road Transport Union (IRU) has over a million members and each of them is at varying levels of technological advancement. In the fierce competition that exists, these 5 supply chain trends are going to result in cost savings that will have a ripple effect right down the value chain. And more importantly, what is the best way to implement them in your own supply chain.

Trend #1 The new breed of Supply Chain Players will be less Asset-centric

Data is already proving to be a big differentiator. We are going to see the rise of a new breed of logistics players who will not own assets but will provide logistics services by leveraging data from those who have those assets. We already have Shype and Zipments who have discovered this space and are providing freight quotes and trucking services at 50% of the normal cost, only because they do not have to maintain any assets.

The non-asset-based carriers are like e-brokers that offer their clients the advantages of flexibility. By tapping the power of digitization, they can view the availability and rates of various partners and connect their clients to the most appropriate asset-based carrier company. E-brokerage will gain ground as we move ahead based on the study by Forbes.

Crowd shipping will require reliable real-time data from innumerable sources There will be on-demand pickup solutions that will also provide on-demand storage and retrieval. These features will become quite commonplace for customers.

Also read : Robotic Process Automation vs Traditional Automation

Trend #2 Circular Supply Chains will be big in the future of logistics

Government regulations on waste disposal and increased incentives for ‘green energy’ will push companies to consider:

- Adopting electric and solar-powered vehicles in supply chains

- Eco-friendly warehouses that will implement advanced energy management systems

- Shifting from linear to circular supply chains

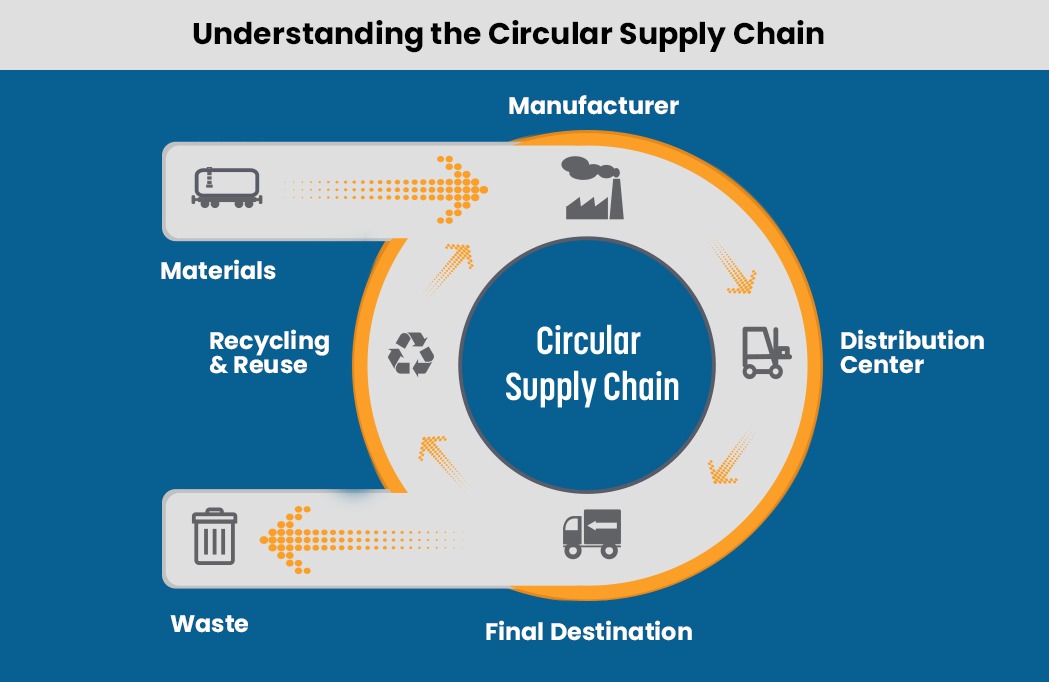

Circular supply chains are a move away from the’ take, make and throwaway’ liner model. The latter is the model where material is discarded after use into landfills and much of it is also polluting our lakes and seas. The severity of this problem is clearly seen by the discovery of a plastic bag in 2019, in the Mariana Trench – the deepest point in the world’s oceans.

The circular supply chain is a more sustainable moded that creates a closed-loop system. It takes discarded material, such as packaging, breaks it down to its raw form and reuses it. The existing initial investment required to make these process changes will be worth it in the long run by spending less on raw materials while helping sustain the environment.

Harvard Business Review’s research indicates that brands that have sustainability advocacy will grow 5.6% faster than those that don’t Going green in logistics will be a defining trend.

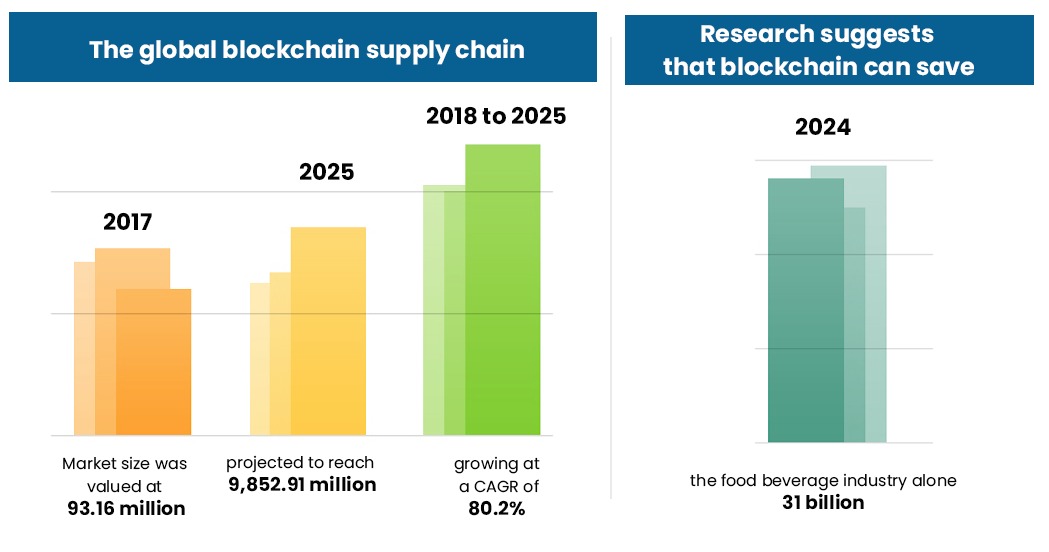

Trend #3 Blockchain technology will negotiate smart contracts

Blockchain in supply chain has shown a greater adoption among global companies and more businesses will use this technology to minimize disruptions and improve transparency. The global supply chain market size for blockchain is expected to grow by CAGR 80.2% by 2025.

There is a reason why blockchain in supply chain is gaining momentum. Data sharing through the supply chain is a known problem and blockchain will bring more transparency. A warehouse manager need no longer worry about goods not reaching in time or ponder whether lon the advisability of egal disputes with suppliers.

The greater adoption of blockchain in supply chains will see the evolution of new kinds of services. Mobile freight brokerage being the foremost of them.

Also read : 6 Questions to Ask When Choosing a Technology Partner for Cloud Data Migration

Trend #4 Extensive Adoption of IoT

IoT refers to the system of interconnected devices that allow the transfer of data over networks without human intervention. IoT technology is already connecting warehouses, transportation modes as well as retail outlets through the use of sensors. Live tracking updates is available not only on shipping and delivery but also in production, inventory management and predictive maintenance.

Many companies are using the big data collected from IoT devices and integrating it with business intelligence software to make data driven decisions for their supply chain strategies. IoT with blockchain can be integrated into one powerful solution for real time logistics tracking and transactions.

Trend #5 Autonnomous vehicles and truck platooning will save fuel

Autonomous fleets might be the future of logistics. Amazon has pioneered this technology through the use of drones for last-mile deliveries. Before drones though, we already had fully automated forklifts. In the cavernous warehouses,human involvement is time-consuming and laborious. On the other hand, vision guided mobile robots are able to process orders and pick up goods, 4 times faster than a human could.

Supply chains of the future will be even more advanced using truck platooning and autonomous trucks. Truck platooning is the linking of trucks in a convoy system using connectivity technology as well as autonomous driving support systems. The connected systems align speed, acceleration and braking. While there is a driver, as of now, in each truck, they only intervene when needed.

Presently Minesota state law, for instance, allows upto 3 trucks to tavel in a truck platoon. The advantage of autonomous truck platooning is that when vehicles are travelling in each other’s slipstream, it saves fuel and lowers CO2 emissions leading to cost savings. The lead vehicle can save up tp 10% on fuel, the middle 17% and the third truck can save up to 13%. In the future, it is expected that 50% of all fleets will have some level of autonomy with some even becoming fully autonomous.

Automation of supply chains will not only be on-road but will extend to the shipping and cargo industry as well. The first automated ship, This technology has been tried for the first time in the Mayflower, which is the first ship to have no crew and runs on solar energy. It uses IBM AI as well as cloud and edge technologies and has proven to be a cost-effective alternative to manned ships.

Breakthroughs in technology will push the boundaries of the logistics industry. However, most technologies for the near future will be based on AI , Machine learning and IoT. Speak to our experts on what is the best way to optimize supply chains and how to implement them into your system.